UGL Limited has been on a journey to fundamentally change its operations, in order to get ahead of the industry curve and continue to see the $2.3 billion business grow.

The company, which trades on the Australian Securities Exchange, is a leading provider of end-to-end outsourced engineering, asset management and maintenance services with a diversified end-market exposure across the core sectors of Rail, technology systems, power, resources, water and defence.

With over 8,000 employees (including subcontractors) across Australia and South East Asia, the company partners with some of the world’s largest blue-chip companies, government agencies, and private enterprise/public institutions.

It is not an easy task to revise the supply chain strategy of any company, as it is intrinsically linked to daily operations. Dean Newman, Head of Supply Chain for Rail Freight at UGL, explained the Rail Freight business’ journey in detail. He said: “Our underlying fundamental principle is the maintenance and construction of assets; that’s the same regardless of sector. With regard to Rail, the building of assets has changed; there’s not the mining boom that there once was and the construction of heavy rolling stock has declined as a result.

“Importantly, UGL currently remains the only builder of locomotives in Australia. In the build space, we are General Electric’s representative in-country. We build locomotives either as a co-OEM (Original Equipment Manufacturer) product or as a GE product under licence supervision. We have a co-OEM product that we build with them; the C-44 locomotive. As the landscape changed, where we were a large prolific builder of locos and wagons, now there is far greater emphasis on the maintenance of assets.”

Strategic shift

As such, the supply chain that underpins the Rail freight business has had to shift radically. The primary shift has been moving away from an inventory push methodology associated with materials pushed into the supply chain, to support the build of locos and wagons: UGL now has to be far more dynamic, adaptive and aligned to what the customers expect from the firm.

Newman said: “We hold a unique position now. Most of the locomotive manufacturers exited in the last 12 to 18 months because of the low demand. So in today’s world we’re adopting an inventory pull methodology. Over the last 12 months UGL has been driving the implementation of a really robust sales and operations planning (S&OP) process, where we endeavour to get marketing information from customers (internal/external), look at historical consumption and insert a predictable variability factor, because in the maintenance business you’re always going to have emerging type work. It’s all about trying to build the right forecast model”.

“Our ultimate objective is a dynamic supply chain that is responsive to our customers. But more importantly it will become a fundamental enabler for the reduction of inventory held within the business and will improve the ROCE (return on capital employed), making sure inventory is not on shelves being lazy; it is actually working for us”.

“Two years ago we were very much in the build space and now that shift has seen the supply chain change to the maintenance of assets instead. Historically we had a business referred to as the National Freight Parts Sales, which had rendered supply chain capability.”

UGL has now implemented a more robust supply chain focusing on operational efficiency, core competency, and total quality management across its Rail division. Inventory management has also improved, with sales and operational planning helping to move from the push to pull methodology in response to changing market needs.

Implementation in Australia

The Australian engineering and Rail sectors spent a lot of time where a push supply chain strategy was the best option according to Newman, because it was simply more important to keep customers’ rolling stock moving in industries such as mining. Compared with the FMCG (fast moving consumer goods) world, which has a far more mature advancement of pull strategies, mining and Rail have been slower on the uptake.

Newman suggests the Rail industry in Australia is now also awakening to this pull methodology though. He said: “It’s been a tough road at times because it has been a paradigm shift from the way in which the business operates, and the entire mindset has to change. We’re moving from buying ‘just in case’ and trying to push that to a market where we move to a strategy that says ‘no, let’s understand what we will need and when we will need it.”

“Implementation of pull methodology on inventory stocking is a key focus for the supply chain function, as has been the ‘rights’ of the customer, be that internal or external. An internal customer is where we are facilitating movement of materials for one of our maintenance or build facilities that maintain or build locomotives all over Australia. Externally, some customers maintain their own assets, so they would procure their own materials from us to facilitate their asset management.”

At the same time, UGL has been incredibly focused to ensure this operational shift does not result in a decline in its customer service offering. This has been an absolute deliverable for the firm as it has transformed the supply chain over the last year. “Competition is no longer between companies, it’s between supply chains.” added Newman. “It is difficult to compete on price, brand loyalty is diminishing, there are low-cost economies all over the world; but a supply chain that delivers the right product, in the right place at the right time, and for the right customer in the right quantity and quality … well, you can’t beat that.”

Key differentiators

UGL’s Rail division, which falls under the Rail, Defence and International (RDI) umbrella, has a strong philosophy of being an employer of choice not circumstance. Despite the reduction in the manufacturing space, the company has continued to evolve its maintenance division though diversification of services.

This has resulted in a new component overhaul division (COD), which is able to leverage its large manufacturing and workshop facilities for wider use. Split into mechanical and electrical, the new division also utilises the strong partnerships it has built in mining and Rail with the likes of GE, Pacific National, Aurizon, Rio Tinto and several other similar organisations.

Newman said: “Many of our customers have some ability to do their own in-house maintenance in their own right. That’s why we sell parts to them as our external customers. But with the (COD) division we service, repair, refurbish and overhaul equipment as new.”

“One of the greatest technology advancements UGL has managed to achieve in the last two years and successfully rolled out over the last six months has been our mobility solutions. We have invested heavily into Service and Asset Management Mobility (SAM) to ensure work execution efficiency and quality is maximised.”

SAM Mobility is a direct user interface for workshop employees to UGL’s quality and material resource planning. Mobility provides portability via an iPad (in a rugged case) so that technicians can perform routine tasks, recognise and create ‘on condition’ tasks, conduct and record ‘strip and quote’ tasks, review and enter measurement points, and record serialised equipment changeovers. UGL is now able to see all open work for rolling stock while out in the field, complemented by 24 hour support crew.

“It has changed the world of our service technicians, they’re now able to create service orders, and give real-time updates. It drastically reduces the risk of errors, has improved stakeholder engagement and provides excellent supply chain visibility. Giving technicians access to our systems and engagement of communication tools, like having email accounts and internet access has had a positive employee engagement spinoff which is truly wonderful,” added Newman.

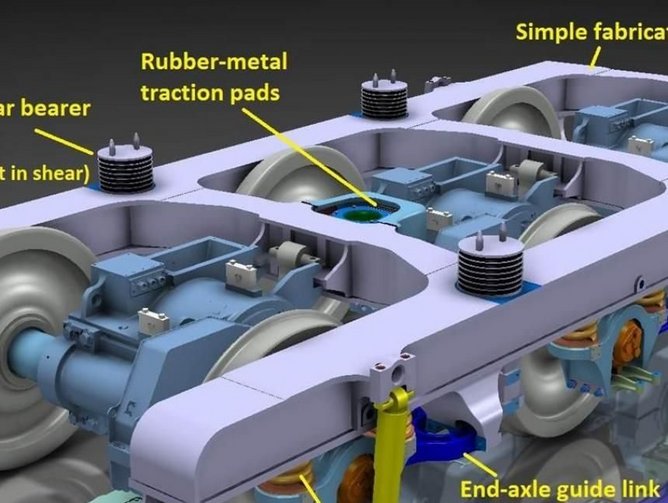

If this wasn’t impressive enough, UGL has also brought its own unique industry product to the market. The FlexiCurve™ bogie is UGL’s premium locomotive bogie, providing significant benefits in locomotive performance, reliability and maintainability. FlexiCurve™ is a family of bogies for applications ranging from 90t, 1 metre Narrow Gauge through to 160t, 1.7 metre Broad Gauge. UGL won the Regional (Newcastle) Engineering Excellence Award for this earlier in 2015. Developed in Australia by UGL Limited, the FlexiCurve™ has become GE’s bogie of preference when selling locomotives out of North America, something the company is incredibly proud of.

Asked about what the future holds for UGL, Newman concluded: “The outlook is positive in that we’ll continue to diversify and serve our customers with exceptional customer service, and as we migrate from a push to pull inventory strategy it will help us to help them. We’ll also be able to take a far greater level of proactive, pragmatic deliverables as we move forward with our technological solutions, so we’re in a very strong position in that regard.”

When the world and its industries change once more, UGL beyond all others will be very well positioned to maximise the upturn potential.