Shamrock Civil Delivers Safe, Sustainable and Smart Solutions

Established in 1994, Shamrock Civil Engineering is Queensland’s leading tier two civil construction company. Shamrock works all nationally and internationally to provide a diverse range of civil engineering services to their clients, including design, site clearing, bulk earthworks, civil construction, roadworks, demolition and large scale electrical, plumbing and communications services. The Company is based in Southeast Queensland with head office and workshop in Ipswich as well as offices in Mackay, Townsville, Dalby and Port Moresby.

Shamrock Civil Engineering is dedicated to servicing the needs of a growing portfolio of high-profile clients, including QGC, Arrow Energy, DTMR, Lend Lease, Glencore, Watpac, John Holland, Mirvac, Hutchinson Builders, Laing O’Rourke, Abigroup, Thiess, Origin Energy, CS Energy, Brisbane City Council, Logan City Council, Mackay Regional Council, Queensland Urban Utilities.

Shamrock Civil has a fleet of over 100 modern and carefully-maintained equipment, helping deliver successful projects to these clients. Shamrock’s equipment includes a range of earthmoving equipment ranging from skid steer loaders, dump trucks, excavators, graders, rollers, tipper trucks, water trucks, backhoes, sucker truck, scrapers, compactors. All vehicles are GPS equipped and inspected daily prior to use. The Company also employs a team of diesel fitters to perform scheduled servicing of plants, reducing risk of breakdown and greatly reducing any down time.

Robust occupational health, safety protocols, open relationships, cutting-edge environmental management and first-rate quality assurance are at the core of Shamrock’s business approach. Shamrock Civil Engineering is constantly striving to improve products and services for the benefit of their clients and the betterment of their business. Shamrock have achieved federal safety accreditation, and hold third-party accreditation for safety standard as 4801. Their multi-faceted quality management system includes a detailed analysis of client demands prior to the commencement of operation and stringent quality control procedures during construction. They also closely monitor client satisfaction and feedback after completion of work to ensure all expectations are met. Shamrock’s quality management system complies with the Australian standard and is third-party certified. The Company is ISO 9001 accredited for QA, addressing various aspects of quality management and some of the best known standards. Shamrock’s environmental system is third-party accredited to environmental standard ISO 14001.These standards help provide guidance and tools for Shamrock, helping to ensure that their products and services consistently meet customer requirements, and that quality is consistently improved.

Forefront of Development

The booming resource sector has proved to be a significant growth area for Shamrock’s business. They have been at the forefront of developments for South West Queensland and The Darling Downs, constructing important infrastructure which has sped up investment and expansion.

“We're 20 years strong now. We're a leading tier-2 civil construction company working nationwide. We provide a diverse range of civil engineering services to all of our clients,” said Shamrock Civil's CEO & Director Andrew Kerr. He is a construction manager within the Queensland construction sector, with extensive experience in managing large complex civil projects. Kerr has been engaged within the industry for the past twenty five years. He is currently responsible for all aspects of the business from project inception to off-maintenance. As CEO and Director, Kerr works closely with Shamrock team members to ensure that all projects are delivered safely and exceed the Company’s client’s quality and program requirements.

Speaking on one of the Shamrock Civil’s top competitive advantages, Kerr said, “We're very much a relationship based company with a strong focus on safety, environment, and systems, featuring 20 years of experience. We maintain these relationships through open and honest communication.”

Enabling the Company’s competitive advantages is Shamrock’s team of approximately 250 Queenslanders in its employ. “Our people are number one in helping to promote our steady growth. We've got a team of dedicated, highly motivated professionals,” said Kerr.

Expansion into PNG

“The Company is 20 years strong now, and we've been involved in the gas and mining sector for the last 10 years,” said Kerr. We've established an office in Port Moresby. We've recently secured a project on Manus Island for Aus Aid said Kerr. “We've got a five-year growth horizon into the infrastructure and resource projects over there.”

What brought Shamrock into this area of work is that they perceived a need for a quality civil contractor in the transport and resources sector. “We've developed our people and systems to align with that need,” said Kerr.

Executing on new opportunities is part of how Shamrock continues to grow despite some slumping sectors, such as slowing iron ore and coal markets. “We're reasonably diverse. We run four programs in the business: resources infrastructure program, transport and infrastructure program, North Queensland regional based program, and a Southeast Queensland regional based program. We're looking to diversify and establish in Western Australia. Our diverse revenue stream should insulate against any downturns in any particular sector. And we have established ourselves in PNG,” explained Kerr.

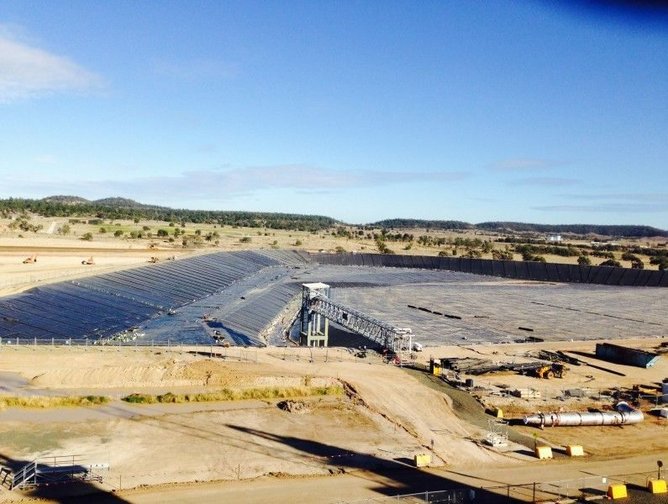

“We're just completing a $76 million joint-venture for QGC,” said Kerr. QGC is a leading natural gas explorer and producer focused on establishing the world's first project to convert gas from coal seams into liquefied natural gas. Shamrock’s joint-contract agreement has been a partnership between Golder Associates and Shamrock Civil. “We’re on target to execute the first concentrated brine pond on time and on budget for QGC,” reported Kerr.

Shamrock Civil were contracted to the Laing O’Rourke & GE Joint Venture for QGC to deliver the Northern Water Treatment Plant. This advanced facility will treat 100 million litres of water per day. The project also includes the delivery of all related infrastructure associated with QGC’s northern gas fields. When complete, it will be one of the largest water plants in Australia. Furthermore, the success of the program is a direct result of successful partnerships like the one with Shamrock Civil, eventuating into more Indigenous Australians entering the workforce and acquiring the skills and experience needed to create a better future for themselves and their families.

In addition, Shamrock is also gearing up for the Manus Island Project in the PNG sector, which is set to commence in February, 2015. “The project involves work for a road from the airport to the township, including road reconstruction and bridges,” said Kerr.

Safety for Life

Behind all the expansion work and projects that Shamrock engages in is the highest commitment to safety on the job. Shamrock Civil Engineering is committed to providing a safe work environment for their employees, sub-contractors, clients and the general public. Shamrock’s operations are compliant with the Workplace Health & Safety Act, ensuring that plant machinery is regularly maintained to the highest standards, and the latest training and instruction information is offered to employees. Shamrock stands by the mantra that there is no task so important that it compromises the health and safety of any individual.

“We run a program called Safety for Life. It's about empowering our individuals to take ownership of safety for themselves. It's about developing a positive culture within the business,” said Kerr.

Kerr went on to add, “Through external accreditation systems we've been OFSC-OHS accredited. We've recently received Federal Safety accreditation. This includes AS4801 accreditation for our safety system.” Through AS4801, Occupational Health & Safety Management System Certification, all Australian businesses have an obligation under workplace health and safety legislation to ensure a safe place of work. Implementing an occupational health and safety management system is a means for managing risk and minimising loss by promoting safe and healthy work practices in their organisation. Shamrock takes this very seriously.

Shamrock’s comprehensive approach to safety includes cutting-edge technology applications. “Some of the technological initiatives that we've taken include UAV's for our surveys. These drones, unmanned aeronautical vehicles, keep our operators out of the line of potential danger created by the heavy equipment we employ,” said Kerr.

Environmental Responsibility and Accreditation

Like the colour emblazoned on the Company’s well-known Shamrock logo, the Company is focused on a clean, green future for Australian commercial enterprise. Their goal is to understand, meet and constantly evolve their environmental approach. While Shamrock recognises civil works cause unavoidable environmental impact, the Company strives to minimise pollution and manage atmospheric emissions to ensure standards are met. This commitment involves implementing stringent environmental processes throughout all levels of management, reviewing environmental policy on a regular basis and implementing practices which minimise risk of environmental incidents occurring on-site. All Shamrock staff are trained in environmental management procedures and are required to report and audit practices as part of their extensive quality assurance measures.

“We're ISO14001 accredited for our environmental management system,” reported Kerr. ISO 14001 is applicable to any organization that wishes to establish, implement, maintain and improve an environmental management system, to assure itself of conformity with its stated environmental policy, and to demonstrate conformity. “We've got a couple environmental engineers directly managing that service. We also have a rehabilitation and revegetation program that we're running in partnership with one of our partners Virotech. For example, we can rehabilitate drill mud into agricultural soil. We can also revegitate existing soil after completing certain projects, which saves us from having to import topsoil. We've also got a product that can treat the existing earth and enable new growth,” said Kerr.

Commitment to Local Community

Part of what makes Shamrock so successful is their comprehensive, well-rounded approach to everything they do. This includes a deep-rooted commitment to their local community. Shamrock endeavors to remain open to feedback for continuous improvement and increasingly safe and mutually beneficial solutions. Shamrock Civil Engineering is committed to ensuring its projects deliver a positive outcome for both clients and the community.