Headquartered in Vancouver, Canada, New Gold Inc. is an intermediate gold mining company with a focus on environment and social responsibility. The company has a growing portfolio consisting of four producing assets — the New Afton Mine in Canada, the Mesquite Mine in the United States, the Peak Mines in Australia and the Cerro San Pedro Mine in Mexico — and three development projects in Canada and Chile.

Peak Gold Mines has inspired the Canadian miner to do more with less, which includes integrating new systems to optimise overall production and performance.

Under this formula, Peak Mines has turned strategy into action by harnessing the creativity and passion of its team while introducing business processes that are lean and continuously improved. The Peak Mines in Australia has been a shining example of the success that incurs from these processes being put into place.

Maximising opportunities

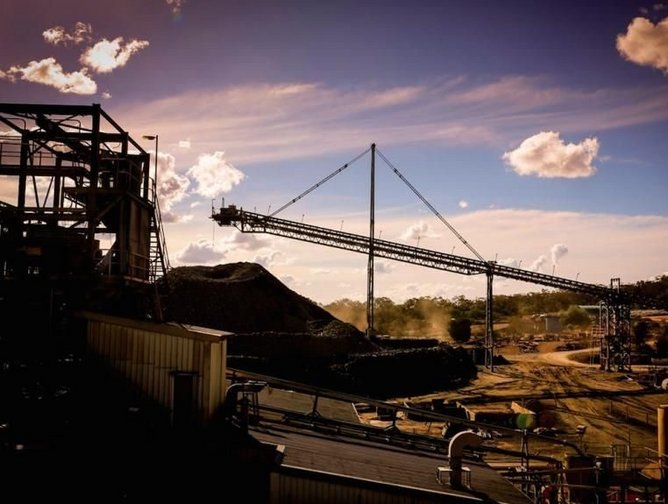

Located in the Cobar Gold Field of New South Wales, Peak Mines is a medium-sized gold and copper mining operation, comprised of five commercially active underground mines and a copper-gold processing plant. The mine produces gold dore for sale at the Perth mint and copper concentrate that is sold to markets in Asia.

Although New Gold has historically been focused on copper and gold, there is potential to maximize new opportunities at Peak Mines, according to managing director of Peak Mines, Greg Bowkett.

“We have a couple ore bodies with lead zinc that affect the current concentrate and we have to pay penalties because of this. So one of the things we are exploring is whether we could potentially reconfigure the circuit to produce a saleable lead or zinc product to turn this from a cost to a benefit.”

Though it is early in the evaluation phase this could enable the mine to access new parts of different ore bodies, which aligns with its strategy of maximising opportunities.

“Should this prove viable, this would add to our current operations and would give us the opportunity to maximise the whole asset instead of just the parts of it we are currently focused on,” Bowkett added.

Refining management and culture

For Peak Mines, structured communication has been instrumental in changing the company’s management style.

The mine has enlisted the help of Quest Worldwide, a global change management consultancy that works with organisations to improve their business performance. The partnership focuses on three fundamental areas: operational excellence, strategy execution and people management.

“Quest Worldwide is a global change management consultancy,” said CEO Mark Pinchen. “We operate from regional bases in Australia, Europe and the United States. We work with our clients to engage their people in deploying their strategies and realising significant, sustainable improvements to their organisations and cultures, delivering real bottom-line impact.”

“Quest has been vital in getting the different departments of our mine to understand our processes so we can achieve our goal. It’s been monumental for the people management aspect of our business,” Bowkett said. “Quest has helped to engage our people, get them out of their comfort zones and to start thinking at the business level. It boils down to everyone understanding and speaking the same language.”

According to Pinchen, this is exactly what Quest does.

“We help their clients and their people to think innovatively about the business at the business level and to then apply the disciplines to realise the vision, goals and plans that are formed. It takes courage and commitment and forces people outside of their comfort zones, but also builds new awareness and powerful ownership of the solutions and requirements. It’s a challenge to involve people in this way but it pays dividends.”

The partnership has aided Peak Mines in creating a high-performance culture that is focused on improving customer relations while continuously driving improvements.

“We value integrity, commitment, innovation, employee development and teamwork,” said Bowkett. “We believe our business can be run through these values and we’re committed to implementing a positive change.”

Quest works with project leaders to implement a coordinated approach to improve project effectiveness with a two-way communication style.

“Instead of our company only being driven by the general manager or CEO, we actually want it to be integrated,” said Bowkett. “We want our company to be driven by the leadership side and the workforce side so we can produce the best product possible.

Another component to refining the Peak Mines’ commitment to employees and company culture has been the assistance of the Workplace Health and Safety Committee (WHS), a safety group comprised of key employees, including a member from every department in the organisation. It has been crucial in strengthening the company’s safety culture and getting Peak Mines to look at the bigger issues.

“WHS has helped change the culture of our people to be more proactive in recognising safety issues,” said Bowkett. “The committee really helps to align our focus on the values, teamwork, and development and training of employees to ensure they understand how we view safety and what is needed to achieved it as a team.”

Operational excellence

With a new approach, Peak Mines has also been able to streamline processes and optimise results. The company’s newly adopted management approach to maintenance, which incorporates the lean manufacturing model, helped Peak Mines cut its maintenance costs by USD $1.3 million in 2014.

“The improved management approach is making a tremendous difference in how we operate and conduct business,” said Bowkett. “The results speak for themselves. The lean model has given us a goal for our bottom line, which helps us know exactly how many people we need to run this operation successfully, and profitably.”

Peak Mines has reduced its maintenance cost on its loaders from USD $120 per hour to $50 per hour. The company was then able to increase its jumbo uptime from 60 percent to 85 percent. In addition, Peak Mines commissioned the help of Kepner-Tregoe to assist with a wide range of business improvements such as increased operational efficiency and overall equipment effectiveness.

“Kepner has helped us select the best locations for equipment to give us maximum capacity,” said Bowkett. “The company has essentially given us more opportunities with what we have.”

The next chapter

Along with additional exploration projects lined up, New Gold will continue to evaluate opportunities associated with the lead and zinc or at Peak.

“Right now we’re focused on mining at the rate that’s optimal for us, while continuing to keep our employees safe,” Bowkett said. “Our Penalty for Profit initiative is another aspect we’re going to focus on moving forward.”