Founded in Germany in 1844, servicing freight barges along the Rhine, today JF Hillebrand has a presence in every major beer, wine and spirits market – both production and consumption – around the globe. With its headquarters in Mainz, Germany, the business has more than 58 offices around the world with a workforce of more than 2,500. Locally, JF Hillebrand has offices in Sydney, Adelaide and Auckland.

Australia and New Zealand are known around the world more for their wines than beers or spirits, with 80 percent of JF Hillebrand's local business focused on exports and only 20 percent on imports.

JF Hillebrand deals with more than 500 customers throughout Australia and New Zealand, amongst which large clients industry stalwarts such as Treasury Wine Estates (responsible for Penfolds and Wolf Blass amongst other brands), Accolade Wines (Hardys), Pernod Ricard Winemakers (Jacobs Creek), and Casella Wines (Yellowtail). While these customers each ship several thousand containers each quarter, JF Hillebrand also caters to smaller businesses producers who may ship as little as a single case of wine each year.

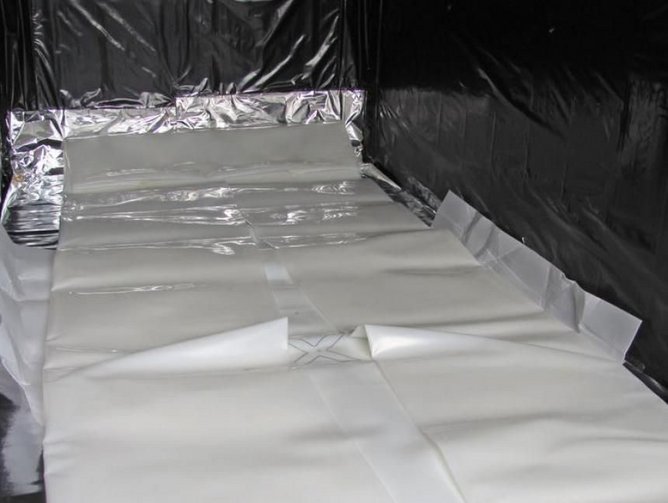

The United Kingdom is Australia’s largest export destination by volume accounting for 32 percent of all litres exported. Interestingly while China only represents 12 percent of litres exported it has just become their number one market by value and continues to grow. The UK market is heavily influenced by the major supermarket chains such as Tesco, Sainsbury’s, Marks & Spencer, and Waitrose with more than three quarters of this wine shipped in bulk and then bottled in the UK. Bulk wine travels across the globe by sea in 24,000-litre flexitanks fitted inside standard 20 foot shipping containers.

“Shipping wine overseas in bulk can offer advantages compared to finished bottled product both financially and environmentally while preserving the quality of the wine. Indeed the quality of wine arriving overseas in flexitanks is no different to that bottled in Australia, due to the wine being less affected by temperature shifts experienced when crossing the equator en route to the Northern Hemisphere,” says Michael Frogbrook, Managing Director for JF Hillebrand Australia.

Given the evolution over the last decade of the major global wine markets to ship in bulk and bottle at destination, in 2007 the JF Hillebrand Group had the foresight to purchase Trans Ocean Distribution (TOD), the market leader in flexitank production and technology. This acquisition included three factories in China, Malaysia, and South Africa as well as a dedicated R&D team who continue to develop and enhance the flexitank product including tailoring specific bespoke solutions for individual customers.

Shipping lines were initially hesitant at the concept of fitting flexitanks inside standard containers, as early efforts would cause containers to bulge – making it difficult to slot them amongst other containers on a ship. Containers equipped with flexitanks also need to be handled with care, especially on trains and trucks, due to the forces at play when moving such vast amounts of liquid in a single container.

However having an in-house manufacturing base for flexitanks (and other industry related products) placed JF Hillebrand Group in a unique position of being in full control of design, quality and performance of the flexitank - and the technological advances made have now virtually eliminated these concerns. As with many technologies there are numerous options available but due to a number of incidents with bulking tanks leaking on ships and wharves, most reputable shipping lines now refuse to carry flexitanks if they haven’t been approved by an independent body – the Container Owners Association (COA). JF Hillebrand Group is one of only two approved suppliers.

In some countries the import duty on bulk wine is lower than bottled wine, giving JF Hillebrand another economic advantage, plus bottling at the destination helps create local jobs. The use of flexitanks also allows Australian wines to significantly lower their carbon footprint from the vineyard to the shelf, which is important in the UK market where many retailers include carbon footprint information on product labels.

“This was highlighted a few years ago at a major wine show where the carbon footprint of a bottle of New Zealand wine on a UK supermarket shelf was much lower than the footprint of a bottle of French wine on the same UK supermarket shelf," Frogbrook says. "To put that in perspective, Auckland is over 12,000 miles away from London while Paris is only 200 miles away – the carbon footprint per litre when shipping wine in bulk across the world is tiny." Bearing in mind that depending on the style of the wine and its region of origin it might have to be bottled in the region of production, meaning that it cannot be transported in flexitank.

JF Hillebrand offers a multitude of valued added services to the beer, wine and spirits industry such as transport management, information management, cargo care & safety, integrated logistics solutions, and customs brokerage.

Underpinned by a bespoke operating system (used by all JF Hillebrand offices globally) developed in-house by their own dedicated IT division, it is totally customised for the industry. The company offers customers free access to its various logistics software products covering sales, operations, finance and supply chain management, including to a real time order tracking tool. Additionally the company creates interfaces into customer ERP systems which eliminates a lot of manual data transactions between both parties reducing errors, saving time and generally increasing efficiency.

"In a more a more competitive environment, our clients need integrated logistics solutions enabling them to better anticipate and control the efficiency and global costs of their supply chain in the long term.”