Quality Danish shoemaker ECCO Shoes has shifted its focus eastwards in recent years. By moving functionalities to Singapore, the company is now closer to its substantial Asian manufacturing base, and is driving innovation across its supply chain. Quickly becoming one of the regional industry leaders has just been one effect of the move, explains Supply Chain Director Scott Phillips. The city-state boasts fantastic infrastructure links and one of the most business-friendly environments in the world, both of which Phillips and his team have leveraged to build a fit for purpose operations hub. Business Review Asia speaks to him at length to learn how this was achieved, and what challenges have been overcome.

Operations

Founded by Birte and Karl Toosbuy in 1963, ECCO has always adhered to the Scandinavian philosophy of functionality and simplicity. Still a family business five decades on, the company has swelled to produce 20 million pairs of shoes per year, going out to nearly 90 countries with a 19,500-strong workforce worldwide. ECCO, despite its size, owns the majority of its assets. “We are almost 100 percent owner operated throughout our production operations,” Phillips explains.

“We make the leather, we make our shoes; we own a lot of our own warehouses. We also have owner operated retail space and e-commerce platforms. Our strategy is to to grow the owner operated footprint in both retail and e-commerce.”

For ECCO, moving operations to Singapore was crucial. Phillips says: “The aim is be closer to our operations; 70 percent of our manufacturing is in Asia - Indonesia, China and Thailand, and the other 30 percent is in Europe.

“Having the daily global operations in Denmark, which is a long way away from Asia, made things a bit difficult. Also the access to new talent pools in Asia is seen as an opportunity for running companies completely based in Asia.”

Meeting the talent challenge

Singapore was initially somewhat of a double-edged sword when it came to recruiting talent, but Phillips and his team overcame this in their own unique way. He explains: “Singapore is an interesting place. Obviously there is not much labour intensive manufacturing here, so getting people experienced in shoemaking is near impossible unless you expatriate them.

“Singapore is a melting pot of cultures and talent within supply chain but not specifically in shoemaking. So when bringing operations out to Singapore, the challenges were the opportunities and the opportunities were the challenges so to speak.”

With the majority of staff well-versed in supply chain operations, the task remained to ensure that they understood ECCO’s decades of shoemaking artistry. Phillips explains: “When someone joins the company we endeavor to send them to a factory to make a pair of shoes, so they literally come back wearing their own pair of shoes, which is pretty cool. We call it the ‘cow to shoe programme’ and this gives our people a huge amount of insight.”

“That's the industry part and then we have ongoing personal development. We use performance appraisals and other employee engagement tools. We generally use the rule 70 percent hands on, 20 percent coaching and 10 percent academic as a general rule to keep developing people going forward.”

Recruiting for roles such as order fulfillment and freight logistics professionals is challenging – the country is a regional logistics hub, and demand for talent is high – but ECCO is able to successfully compete in this field by ensuring that its positions are both attractive and rewarding.

“When it comes to manufacturing and planning operations this is much more difficult,” Phillips says. “So we have had to really then leverage on different industries, different approaches, looking outside the box and finding people from different backgrounds - they just need the right persona.

“We spend a lot of time developing and educating them, getting them into the industry, understanding how to make shoes, the complexities of the industry itself. That has been a challenge. At the moment we have a stable team which we're now working on strongly developing.”

Disrupting the supply chain

ECCO bucks the trend when it comes to supply chain operations – it owns and operates almost 100 percent of its assets. A facet of the business, Phillips explains, which gives the company control of where and when its products will arrive in stores.

“We have an extremely complex network from end-to-end, probably made more complex by the fact that we control every step of the way,” Phillips says. He goes on to explain that ECCO has around 200 different supply chains for its materials coming into the factories. “We have five factories that are converting materials into shoes, and we have about 70 shipping lanes going into the first port market.

“At the end of the day, we are shoemakers. That's our core competency, but we believe that because we own the assets we can glue the supply chain together for a competitive advantage.”

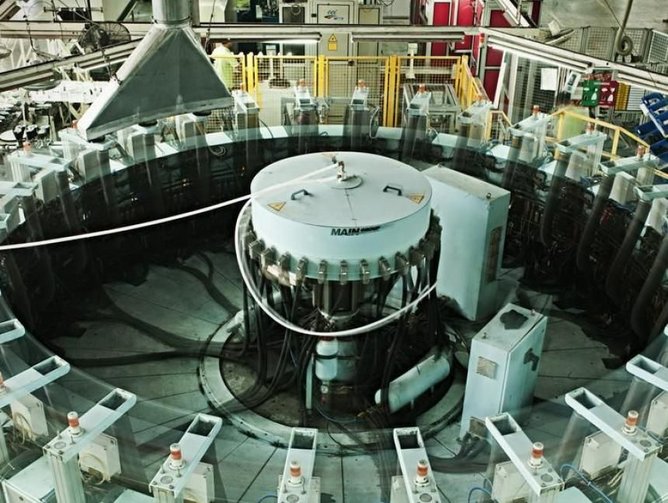

ECCO’s external operations are being further in-sourced. Over the past year the company has leveraged significant investment in order to purchase new machinery in order to bring more manufacturing components inside its facilities. “The company likes to control its value chain from end to end, which is quite amazing. It's rare a company is going that direction these days,” Phillips adds. “We are bucking the trend and that makes this an exciting supply chain to work in because we have all the toys. So the challenge is how we can make them all work together?”

Alongside bringing in the right talent, the timely implementation of innovative technology has played no small part in this growth journey. “I lose the most sleep - other than trying to find talented people – over disruptive technologies and how we can utilise them all,” Phillips adds. “We run a centralised SAP program with an ERP backbone throughout the company and this is a fantastic asset.

“We’re starting to use disruptive companies to run our models for us in parallel to our current program to manage Big Data. We are seeing if we can slowly transition into these new technologies to manage complex supply chains. So far we're managing to do some cool projects.

“If we put data in the cloud, we can be much more flexible when we shift in the market or find a shift in how a customer wants a product delivered,” he explains. “We don’t have to restructure hundreds of people and thousands of man-hours to restructure a module in our ERP. We can grab data from a cloud, bring it down, play with it, send it back up and continue the day to day running of the business.”

Even a matter of days in the supply chain can feel like a lifetime. Trying to pin down what ECCO will look like in five years will always be a cautious prediction; though due to the strength of the systems Phillips and his team have developed, the future certainly looks bright. Continuously improving its supply chain will be central to wherever the company’s next big growth drive occurs. Driving value while maintaining flexibility in the supply chain will be crucial to this growth, Phillips concludes.