Burger King is enjoying a fast-track journey on a growth express in India; a journey which shows no sign of slowing down.

If anything, the quick service restaurant (QSR) operator is about to step up another gear as 60 stores becomes 100-plus by 2017. The global fast food chain only arrived in the country towards the end of 2014, reaching 15 cities in very little time and offering added value through apps and home delivery much quicker than established rivals did several years ago.

A key driver of this expansion and a crucial backbone of ongoing product and service innovation is Burger King India’s supply chain, headed up by Chief Supply Chain Officer Sandeep Dey. Originally holding a packaging innovation background, Dey’s path took him from Unilever to franchise giant Yum!, where he spent six years heading up procurement operations for its brands before taking on the new challenge at Burger King. The journey has been non-stop since.

“The last 18 months has seen amazing growth,” Dey says. “We have successfully positioned our brand with consumers thanks to a uniquely localised menu, made entirely from scratch, with an incomparable guest experience.

“India is a unique market, the taste palates, though is experimental; mostly people like to savour the taste they are brought up with. That is why we have created an entirely new menu for India backed by extensive research and understanding of the local consumer preferences. Special emphasis was given on the extensive vegetarian menu and both our vegetarian and non-vegetarian menu has been well appreciated by the guests across India.

“We are one of the fastest growing companies in the Indian QSR space and we welcome vendors operating in the industry to join us on the journey and leverage our growth.”

Supplier-led innovation

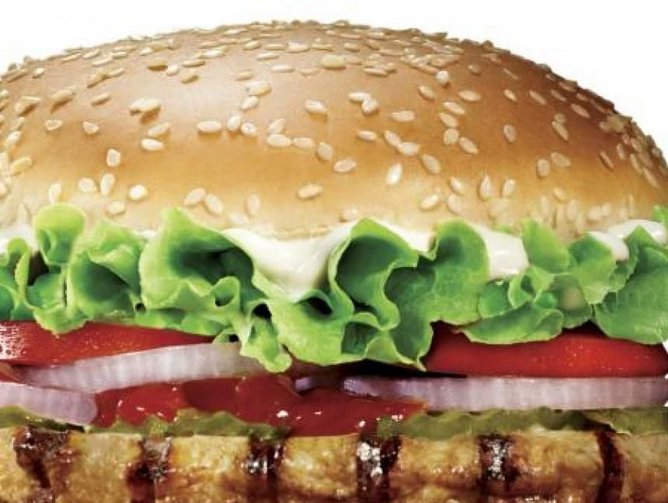

Currently, Burger King India’s supply chain landscape contains fives distribution centres, 21 specialist multi-temperature trucks and around 20 vendors that are responsible for more than 140 skus. This amounts to a spend of 100 million Indian rupees a month, a figure set to double as more restaurants open this year. The network helps to supply a menu containing a range of chicken, mutton and vegetarian products, form its best-selling whopper burgers to tandoori grills.

A rigorous vendor selection process ensures the food lives up to its customers’ high expectations. This involves close examination by Burger King’s global vendor approval programme as well as internal commercial and technical evaluations. Once approved, product samples are gathered and tested in labs at least twice a year.

Vista is the company’s most significant supplier partner, not only in India but also other parts of the world, providing the flagship whopper burger range and many of the menu’s value products.

Dey explains: “We work very closely with suppliers to get the most out of each other – this is our philosophy. As a brand that has just started from scratch, the initial phase involved very close collaboration over menus, kitchen equipment and logistics in order to launch successfully. Our CEOs and top executives all communicate together to make sure we are all going in the same direction.

“Our Supplier-Led Innovation Programme (SLIP) involves partners coming up with their own ideas based on the gaps in our menu and the briefs we set them, who then work closely with our chefs and food scientists.”

Shortlisted entries then go on to consumer research, and once a winner is chosen it is test launched in a region before being rolled out across the wider network, with unsuccessful entries forming a promising backlog of innovation which can be tapped at a later date.

“The suppliers are also tasked to come up with cost reduction options through various product engineering, and we adopt the same process with multiple options being tested with customers in order to make sure quality is not sacrificed,” Dey adds.

“We want to work with vendors who share this vision for innovation. We want to work with vendors who invest ahead of time in terms of people, processes and innovation capability so that we can achieve our goals together. Our volumes are going to increase quickly so there are some brilliant opportunities for suppliers all over the country.”

Rapid growth

Burger King’s immediate rivals KFC and McDonald’s enjoy a reach of 350-400 stores across 30 or more cities, and it is these areas which Dey is targeting for quick expansion. The company is also committed to growing its presence in airports and train stations.

This presents a number of extra demands on the supply chain, but Dey has a number of initiatives in place. “We are creating regional distribution hubs ahead of time to become cost effective as we grow,” he says. “This involves opening a warehouse in an outsourced location which is already used by other QSR operators, meaning our overall costs will be reduced. We are also encouraging our distribution partners to invest in these areas eight to 10 months in advance, ready for when we enter those markets.”

An example of this is distribution partner Coldex Logistics, which has raised close to US$20 million to expand its infrastructure and support Burger King’s future business activity.

Another way of controlling cost of sales in an expanding business is to get involved further upstream. Burger King India has been negotiating with original ingredient suppliers on behalf of its own suppliers, speaking to farmers to ensure fair prices for higher volumes which will pass on savings further down the supply chain.

Technology is also helping Dey’s operations to become more cost effective. “We are optimising inventory levels with the help of technology,” he says. “Instead of analysing bases individually one store and one warehouse at a time, we can see everything in one system. We can see what products are where and how much is at each place – this takes away the need to create buffers.”

By continuing to grow quickly, innovate and impress customers with its QSR experience, Burger King India is set to continue its express pace journey around the country. It is an exciting time for both its supply chain teams and suppliers, with Dey eager to welcome equally innovative and fast-moving partners on board.

“We want our suppliers to continue to invest with us, and we will continue to support and collaborate with our existing partners. Vendors not associated with us we encourage to look at our growth and be part of it,” he concludes.