As one of the largest commodity traders and mining companies in the world, Swiss-based Glencore has maintained a rich lineage of innovative technology through its existence in the mining sector. The company has leveraged its experience and knowledge from its own operational sites to develop and market new solutions to meet the mining industry’s evolving demands.

Their competitive advantage for the last 30 years has been Glencore Technology. Spawned from the merger with Xstrata, Glencore Technology continues to be a dominant player in marketing technologies for the metals and mineral processing industries.

Industry experts

Glencore Technology specializes in developing and marketing supportive technologies for the mineral processing and metals smelting and refining industries.

The company has developed proven technologies such as ISASMELT and IsaKidd, which are patented processes widely used in the smelting, electrowinning and copper refining industry today.

Additional technologies include IsaMill, a fine and mainstream grinding technology, the Jameson Cell flotation technology and the Albion Process leaching technology.

“We’ve initially developed specific copper processing technology,” said Reinhardt Viljoen, Glencore Technology’s Chief Technology Officer. “However, we’re now also involved in the broader design of smelters and refineries and our technology is applicable to other base metals like zinc, lead, nickel, etc. Our technology has also delivered improved processing performance in the precious metal industry, with the gold and platinum industry specifically applying Glencore Technology’s IsaMill and Albion Process Technology.”

In terms of supporting technologies for clients, Glencore Technology has designed and developed the ZipaTank™. According to Viljoen, The ZipaTank is an innovative approach to slurry storage and leaching tanks that incorporates modular components and mechanical joins to provide all the benefits of a traditional welded tank, but with lower costs, reduced installation times and far greater flexibility.

“The tank is mechanically bolted. Anyone with a minimal amount of skill and supervision can bolt it together. Its scalability makes it very exciting for clients as it can accommodate most projects and even be reused for other projects.”

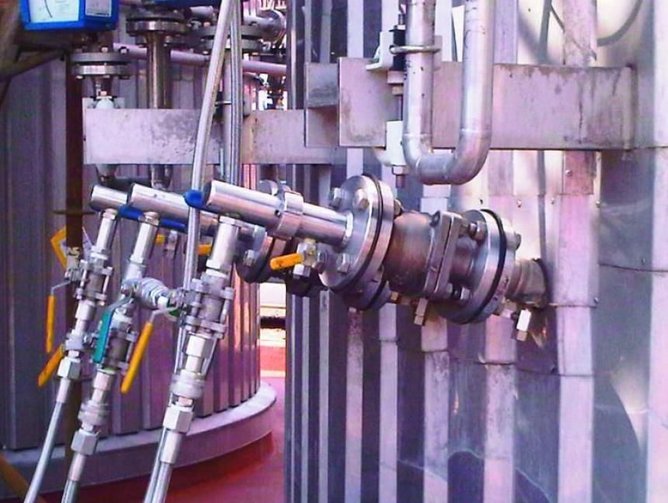

In addition, Glencore Technology has developed the HyperSparge™, a proven and cost effective system for delivering air, oxygen or other process gases into tanks or vessels for leaching or oxidation processes.

“A lot of these technologies started off from issues we experienced in our copper and zinc operations,” said Viljoen.

The key ingredient

For Glencore Technology, innovation starts with collaboration.

“Here in Australia, and all across the world, collaboration is a key ingredient to being innovative. We have a very supportive and collaborative group here at Glencore Technology and everyone brings something to the table,” said Viljoen.

Collaboration helps Glencore Technology continuously find new ways of identifying and developing technologies to improve processing in the mining industry as well maintaining a wide range of existing applications in the mining industry.

Along with working internally with Glencore operations, Glencore Technology partners with other companies to collaborate in building innovative technologies that improve processing. For example Netsch GmbH, Glencore Technology’s partner in the development of the IsaMill Technology.

“Once we identify a need, we run a very lean operation. We know what we’re good at and we stick with it. We excel at commercializing technology and identifying needs. We work with the universities as well carrying out our own research and design to take those ideas to the next level in a very functional and commercial way,” said Viljoen.

“We take great pride in developing processes that are operationally proven and that deliver value to our customers sustainably, such as our fine grinding processes that give mining operations the ability to liberate more of their valuable minerals.”

According to Viljoen, collaboration doesn’t always create innovation; it has to be driven by the needs of the industry and operations.

“We’re heavily driven by our internal Glencore operations to provide them with the expertise we have, and present potential opportunities commercially as we identify them. The mining industry is very conservative. Productivity is a key focus and you need to ensure you’re responding to the needs of the operational guys.

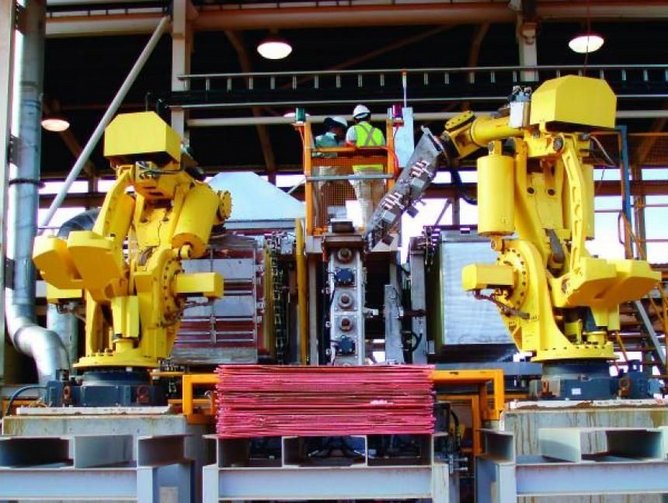

“With the introduction of automation technology, advanced process controls and simplicity of operations will become a big factor in coming years. Automation is complicated but new technologies will simplify the process,” said Viljoen.

“Equipment design needs to be very simple but robust. To maximize productivity, the need is to be innovative around designing equipment and running it with minimal attention.”

In addition, the company continuously strives to find new and more efficient ways of doing things, even if it takes them outside the realm of the mining sector.

“We’re continuously looking for other applications in the mining industry or even if it applies outside the industry. We are always looking for new ideas in terms of solving issues that come up within those disciplines – grinding, flotation, smelting and refining,” said Viljoen.

Branding

One of the most underrated aspects of the mining industry is branding. For Glencore Technology it is especially important.

“You miss opportunities if you don’t. Being active in the market and letting people know what your capabilities are is extremely important, especially if you want to grow. During the mining boom you could get away with a passive approach. You can’t do that now. Branding yourself is very important and we actively strive to do just that,” said Viljoen.

“With the change in the mining industry, and the mergers, there has been a lot of change in our structure. As a result, our presence in the market as Glencore Technology has been more of a gradual change. One of my key focuses as Chief Technology Officer is to get our branding well established.”

According to Viljoen, forming a presence in the market is an important step in growing as a company as well as delivering on your promise.

“We’re motivated by continuous improvements. We maintain long-term relationships with our all our customers to ensure we’re delivering on the promises we’ve made. For us, client feedback is extremely important and these relationships help us to leverage their opinion into making advancements. A key part of our business is making improvements around our customers.”