Applus RTD Is One of the Largest and Most Respected NDT Companies in the Oil and Gas Sectors

A global leader in Non- Destructive Testing and Inspection (NDT&I) that supports clients’ search for optimal asset integrity in industries like oil and gas, as well as conventional and nuclear power plants. By constantly striving to achieve the ideal balance between highly qualified personnel and fresh ideas coupled with new and innovative solutions, Applus RTD offers a unique approach that helps maintain optimal productivity and profitability for every installation. The individually tailored solutions from Applus RTD are developed against a background of global knowledge and expertise, but delivered locally through trained specialists who know and respect clients’ particular situations and needs.

Applus RTD has been operating in Australia since 1981, initially as Pilbara NDT and since 2007 operating under Applus RTD after the merger with RTD Steeltest. It serves both the maintenance and construction markets. The construction division focuses predominantly on providing NDT services on pipe line and LNG construction projects according to Herman J. Quakkelsteijn, Manager Major Construction Projects - Asia Pacific.

Leadership through service and innovation

The Applus RTD Group is an independent operating division of the international Applus+ organization - a concern that is active in the fields of inspection and certification services for a diverse range of industries - from food and construction to automotive and climate technology. Today’s Applus RTD Group, with its headquarters in The Netherlands, started life in 1937 under the name of RTD (Röntgen Technische Dienst). From its early beginnings, RTD embarked on pioneering work in industrial x-ray testing. Over the years, the company has developed new and innovative concepts and support services that have grown and diversified to become the backbone of establishing Applus RTD as a leading global energy service provider: A client-focused approach that provides a pro-active response to changing needs while taking advantage of new technologies for construction, maintenance and inspection. With new developments in predictive and preventive technologies plus tailored solutions that ensure plants are fit for service, safe and reliable, it means clients’ asset performance can effectively be optimized... whatever the challenge.

Four cornerstones for optimized asset performance

To optimally support its clients’ needs for maximum productivity and profitability, their assets must be managed and maintained in a way that delivers the greatest potential for a successful operation. Applus RTD’s technical assurance through non-destructive testing, inspection, and certification in Australia enable this aim to be achieved. Based upon four key ‘cornerstones’ which can individually or together be applied to deliver a precisely tailored solution they enable the essential back-up needed to optimize all aspects of construction, maintenance and inspection projects on a worldwide basis.

Project Management in New Construction is available without compromise to the functionality of existing concepts. Based on specialist knowledge and a flexible approach, new technologies can be seamlessly implemented which coupled with highly qualified personnel mean that solutions can be achieved that prevent downtime, reduce waiting times and remove testing and quality control from the project’s critical path.

Process Integrity Management in Maintenance involves a practical approach to process management using a balanced combination of experience and techniques such as Risk Based Inspection (RBI) and Fitness For Service (FFS). The ultimate aim is to minimize disruption during key inspection operations and thus ensure process continuity and uninterrupted productivity.

Supporting Services and Consultancy are vital aspects in the optimization of an asset’s lifecycle. Knowledge-intensive support is available and is provided by teams of dedicated specialists for disciplines such as Turnaround Planning and NDT Process Optimization. HSQE Audits and Training complete the Supporting Services package.

At the heart of Applus RTD are its people

Highly trained, experienced and motivated specialists: People with a strong sense of responsibility who thrive on the challenge of working independently, and that thanks to on-going in-house training programs, never stop learning and improving their skills. Their inherent knowledge and flexibility mean they can operate in a variety of locations and situations thus supporting the organization’s objectives. Within Applus RTD, personal development opportunities are presented that are based on individual development plans. Special programs for management development and high level technical development for promising employees are also available.

Qualified Approach

A key area of Applus RTD policy is HSQE – to such an extent that all employees and the company itself are qualified to handle a wide range of projects and assignments in this area, in many different sectors. All procedures are tailored to the specifications of clients, government bodies and certifying authorities all over the world. The company also works in close collaboration with those authorities in order to remain abreast of the latest requirements and knowledge, wherever in the world they may apply.

At the heart of Applus RTD activities lies the reporting of testing results. The services provided may typically begin by the selection or development of the optimal testing method. Measurements are then taken ‘in the field’ and a report compiled. For new constructions, this can lead to approval or rejection of a single weld or even a whole installation. In situations involving maintenance, a report highlights the degradation of specific installations or objects, and recommendations are made for suitable remedial action. Applus RTD aims at the provision of immediate reports, without the traditional waiting times of days or even weeks. In this way, efficiency can be enhanced and costs reduced... but never at the expense of safety to people or the environment.

Strong in technology

From its earliest days back in 1937, Applus RTD has always maintained a commitment to innovation and development. As a result, many well-known technologies have been created within the company. Today, many of these concepts are now combined to enable specific testing to be carried out in the most optimal way, thus enabling dedicated solutions that will meet the many and varied challenges that clients put before the Applus RTD specialist. Because Applus RTD has all established NDT&I technologies at its fingertips, it also means that solutions can be found in the shortest possible time. If that is not enough, thanks to a strong technological base and many years of experience, it also means specialized and successful solutions can also be developed to respond to specialized requirements.

Testing Technologies that Guarantee Integrity

Applus RTD can provide an exceptionally wide range of testing technologies – both conventional and advanced techniques, and also tailor-made solutions. In the field of NDT and Inspection technologies employed include radiographic, ultrasound, penetrant, magnetic and visual examinations. Technically advanced methods of NDT can also be provided which have been developed from conventional techniques. A key factor for the success of Applus RTD recommendations is the expertise of inspectors. They determine exactly what is examined and where, how frequently, and the best method to use. They then interpret the data obtained and from this, make conclusions and recommendations.

With Technology advancing as rapidly as it does, Applus RTD readily perceives the importance of frequently assessing new technology. How often? “Every day,” says Quakkelsteijn. “In our Technology and Applications Centres we have academics and engineers visiting trade shows, technology conferences, and meeting with universities; Applus RTD partner with universities with whom we carry out research to ensure we are continuously ahead of the game.”

Very recently Applus RTD developed a Real Time Digital Radiography system to inspect cryogenic welds in LNG tanks for a project in Brunei. The core technology was already developed for pipe line girth weld inspection, however it was never applied on a large scale LNG tank. The development resulted in a dynamic inspection system which is a first in the industry considering all Radiography alternatives are static inspections.

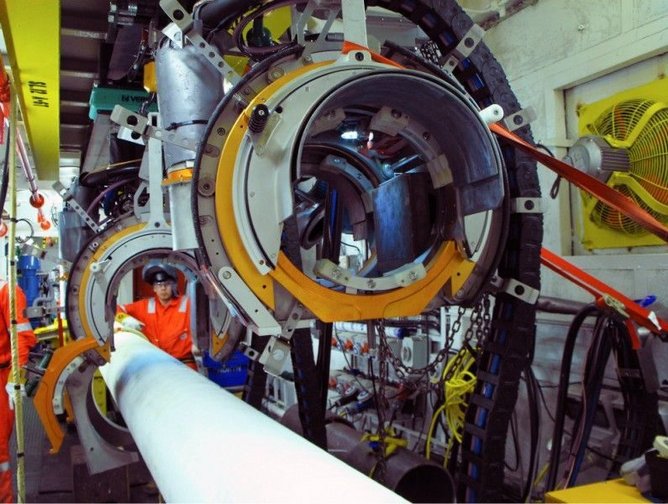

Another example of Applus RTD’s commitment to continuously improve their technology is their AUT equipment which was developed in the early 50’s for pipe line girth weld inspection; first commercial use was back in 1986. “Over the last 30 to 40 years Applus RTD has been the leader in AUT inspection initially with our multi-probe AUT system and then Phased Array AUT,” says Quakkelsteijn.

“And in the very near future the latest technology we’ll be introducing is our RTD IWEX AUT system which is currently being tested in the field. Some key points about the RTD IWEX technology that would help the Company’s clients are that it would “increase accuracy on sizing of defects,” says Quakkelsteijn. “And potentially we're also looking at avoiding the qualification or validation of systems prior to a project. The standard protocol with AUT is that, in most cases, you need to validate or qualify your system. The client sets up a number of test blocks and you have to prove your sizing accuracy; this can possibly be avoided with our RTD IWEX technology, and is something that we hope to achieve. It would be a revolution in the industry.”

“This revolution would be a competitive advantage in the market because competitors would be required to do a validation of the system which is time consuming, first of all, which means we have an advantage over our competitors in that we don't need months and months of prequalifying our systems. Secondly, we'll see decreased costs associated with that — equipment rental, personnel operating the system, etc. — the client will see a great advantage,” says Quakkelsteijn.

The World of APPLUS RTD

Applus RTD is a global leader in all aspects of NDT&I. A leader that is committed to a policy of delivering a comprehensive range of Asset Integrity Services that help ensure that clients’ assets are optimally maintained, safe, productive and profitable. With more than 75 years’ experience in all aspects of NDT&I operations, Applus RTD has gained an ability to develop customized solutions to enhance clients’ process performance and installation integrity regardless of the challenge or working environment.

Thanks to a policy of growth and expansion plus its global information networks, today Applus RTD can deliver these services locally; whenever and wherever they are needed. This commitment to optimizing clients’ asset opportunities is supported by a commitment to innovation and the application of the latest technologies, plus highly motivated and trained specialists who treat today’s toughest demands as an experience that can help with the challenges of tomorrow.

Throughout the organization, quality is a byword. Stringent norms for example, are taken to the limits and then often still further, in the pursuit of the optimum for processes, people and the environment. Quality is also a key factor in the way new technologies and testing procedures are developed, to help keep shutdowns to a minimum and clients’ assets productive and profitable.

Strategy for the future

“There's a world-wide scenario, but for us here in Asia-Pacific in the construction market, the RTD IWEX technology will allow us to dominate the market in the offshore sector where more exotic materials are required, such as CRA or Duplex, those sort of welds are more difficult to inspect with conventional methods so we can dominate the market more -- that's on the pipe line side.

On the LNG side, both technologies, AUT PA and Real Time Digital Radiography will mean reduction of project time and are unique to Applus RTD. Basically we can reduce the duration in construction due to improved technologies,” says Quakkelsteijn.“More on the LNG tanks, that's where we can save hours, if not shifts on just one horizontal or vertical weld, by using this new Real time Digital Radiography technology. Hence, that is where our future focus will be. This will initially be in Brunei where were currently doing our first project with this technology, and then hopefully roll out in the entire Asia-Pacific region where there is an large amount of LNG projects on the radar where we are hoping to get a share of the market once we get a technology edge over the current cheap, local companies there.”

With over 150 systems worldwide, Applus RTD truly is a leader in this market and their continuous commitment to invest in new technology and improve keeps them in that position. “Australia is becoming one of the world's largest LNG exporters. In general, for any energy company in Australia, there is a very exciting future ahead. Based on our technology advantage, we have a very good opportunity to improve our market position, both in the construction and maintenance market.”